What do international Standards of Excellence look like in Additive Manufacturing?

The international standard of excellence for Additive Manufacturing is being able to capture design data (through 3D scanning) for solutions to be designed to the functional needs of the brief.

An example could be 3D scanning a part to design guided drill holes which fit perfectly on the surface of the scanned mesh.

3D printing allows the user to bring the solution to the here and now. Excellence is being able to produce your solutions in a very short time frame with tight tolerances and to be functional immediately.

Individuals must be able to master Autodesk Fusion 360 CAE software to produce design solutions based on 3D Printing Technology used. A strong understanding on build strategies is required, what supports to be used and where, for example.

The individual must also be able to set up a 3D printer correctly based on materials and technology used (FFF, DLP and SLM).

The competitor is required to generate optimised toolpaths using a range of suitable slicer software. The competitor may have changed the design to meet the needs of the functionality of the product.

At the end of the design task, competitors are required to 3D print a physical component in the time limit set.

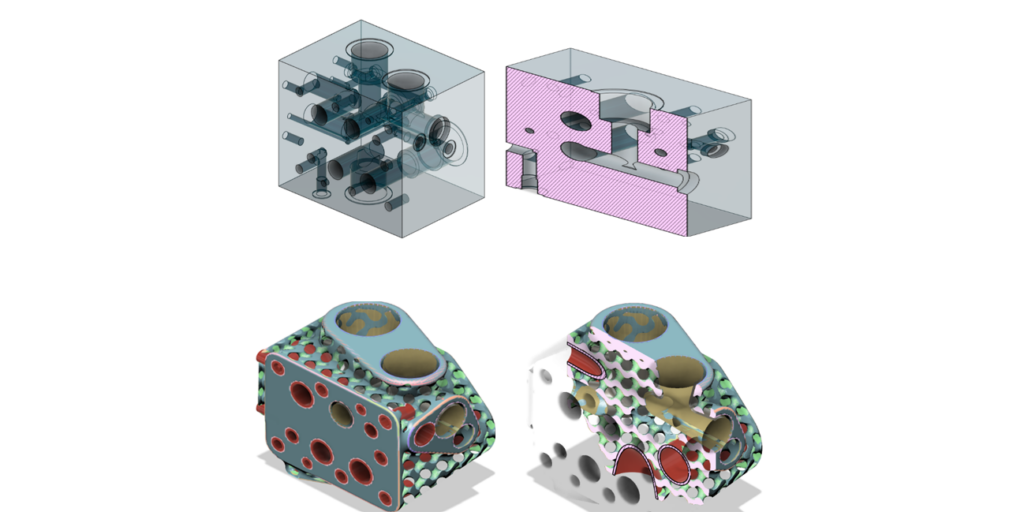

Example: The following model was given to the competitors who were required to re-design the pipework to reduce ‘dead areas’ from the drilled channels and optimise the solution to reduce the mass of the product. Using SLA 3D Printing Technology. Duration 2.5 Hours.